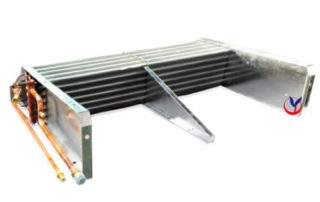

Condenser coil of split-type air-conditioning system is an outdoor component. In wet climates such as Taiwan, the corrosion resistance of metal parts is the key to product reliability. The location of copper pipe welding is the most fragile part. YehJeh has abundant experience and technology know how of process control for u-band auto brazing and inlet-outlet pipe welding.

Faced with a wide range of product types, automatic brazing process require precise parameter control such as temperature, track speed, solder amount, brazing position, etc. In addition to years of experience and mastery of the machine, we will optimize the parameters when creating a golden sample and ensure its reproducibility in mass production.

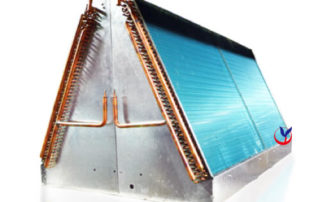

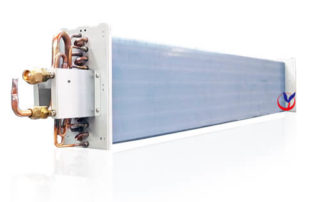

Condenser coil is one of the most important components in refrigeration device. The high-pressure superheated refrigerant vapor generated by the compressor will be condensed to liquid states when it passes through the condenser, and latent heat generated by the phase change will transfer to the surrounding environment. Use of cooling water or surrounding air as the coolant is common in many condensers. There are three types of water-cooled, air-cooled and evaporative, depending on the type of condenser used.Depending on the needs of the condenser, the size and design of the condenser also vary. The condenser

coil manufactured by YehJeh has a wide range of applications in home appliances, transportation, industrial and commercial machines. We have abundant manufacturing experience for mass-production of appliances products and highly customized industrial products.

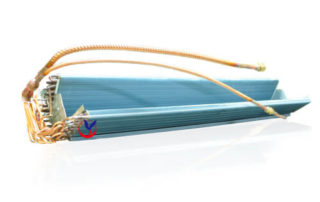

The heat transfer path in heat exchanger system is from the refrigerant to copper tube, then from copper tube to aluminum fins, and finally aluminum fins transfer heat to surroundings. The degree of adhesion between copper tube and aluminum fin is key factor of heat transfer. Duo to thermal resistance of air is greater than metal, if copper tube and aluminum fin are not in perfect contact, air will be added to the heat transfer path. The contact between copper tube and aluminum fin is controlled by the tube expansion process. Yehjeh uses an automatic mechanical tube expanding machine to make copper tube expanding in a true circle and 100% contact with aluminum fins. In addition to the advantages of stable quality, it also has faster processing speed.