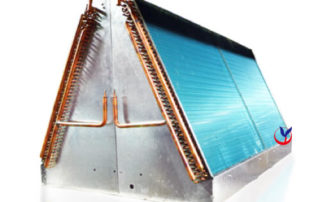

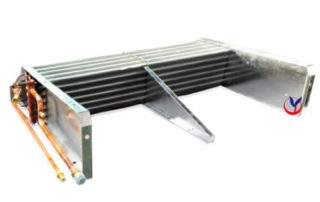

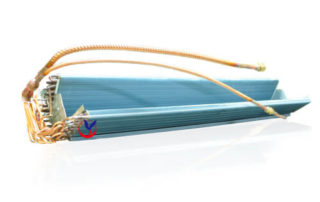

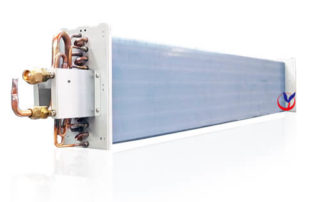

Copper fin heat exchanger

YehJeh provide robust and reliable copper fin heat exchanger which can operating in harsh environment including mining machine and any heavy-duty vehicles, marine application and military equipment. Copper fin heat exchanger has superior thermal conductivity, corrosion resistance and strength compared with aluminum, it is the ideal choice for demanding environments. Cu provide the great corrosion resistance to maximize service life. They are also suited to more abrasive environments because unlike a pre-coated fin, a copper finned coil will not wear out and fail.

Heat exchangers are devices that transfer heat in order to achieve desired heating or cooling. An important design aspect of heat exchanger technology is the selection of appropriate materials to conduct and transfer heat fast and efficiently. Several different fin material options exist, allowing the heat exchanger to operate in environments ranging from home appliance applications through to more aggressive coastal and manufacturing environments. YehJeh provide 3 key fin materials commonly offered in HVAC system: Aluminium, a pre-coated Aluminium with hydrophilic or hydrophobic coating and Copper.

The combination of these properties enable copper to be specified for heat exchangers in industrial facilities, HVAC systems, vehicular coolers and radiators. And also used in very harsh industrial facilities including fossil and nuclear steam generating electric power plants, chemical and petrochemical plants, marine services, and desalination plants.