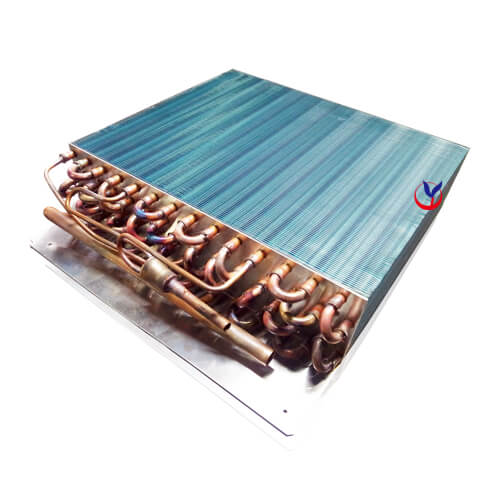

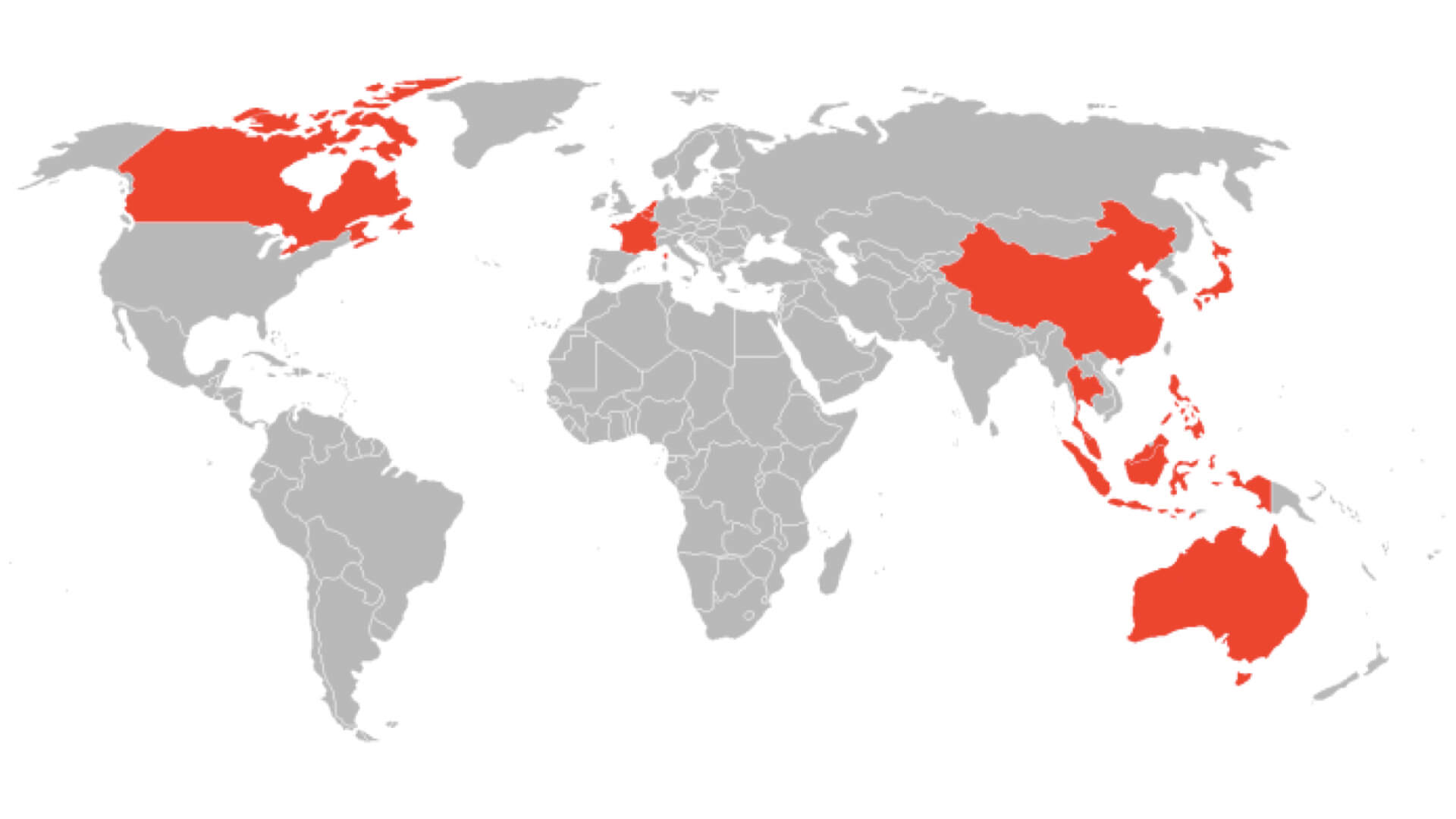

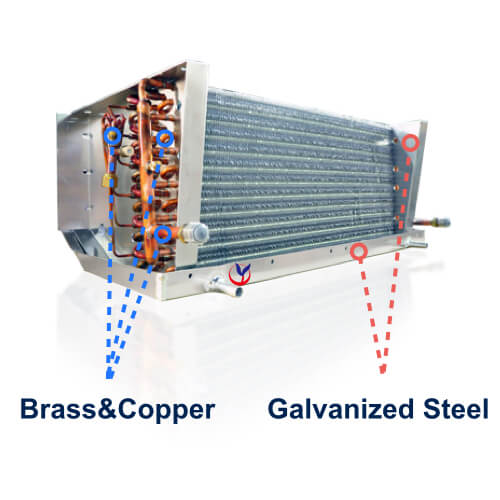

YehJeh’s ice maker condenser products have wide range applications. Our variety fin and copper tube material and flexible process can meet your special needs. Nearly every type of food service business needs an ice machine. Commercial ice machine parts are typically used in ice makers for foodservice, lodging, healthcare and convenience store applications.

Commercial ice machines generally fall into 4 basic types including modular or ice machine head, undercounter ice machines, countertop ice dispensers/makers, and combination ice/water machines. The ice shape can fall into 5 types including full-cube ice, half-cube ice, commercial nugget ice, commercial flake ice and commercial gourmet ice.

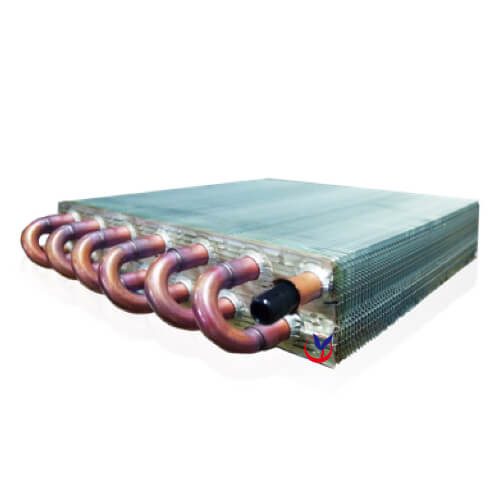

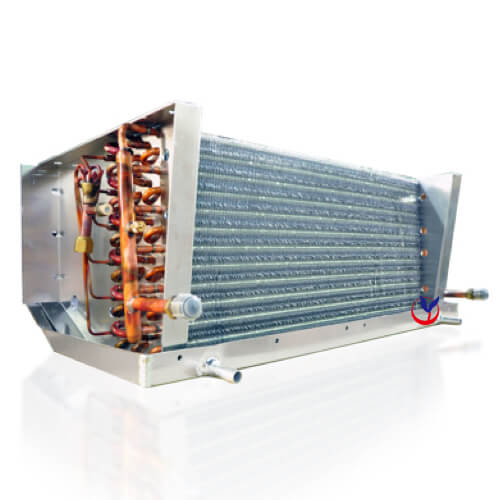

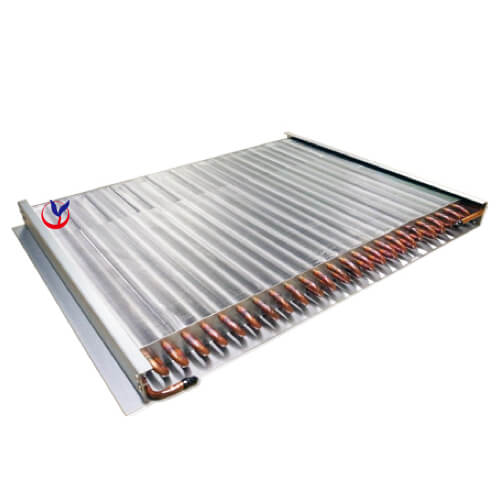

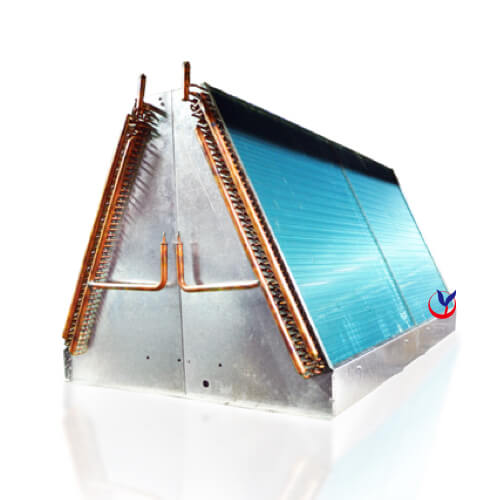

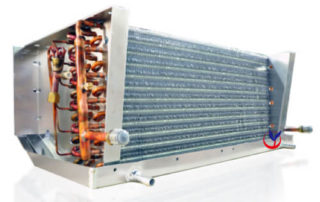

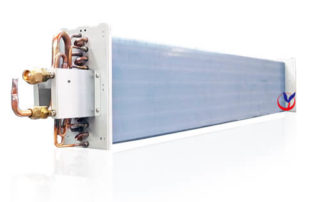

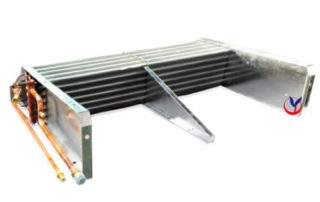

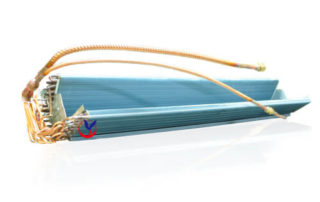

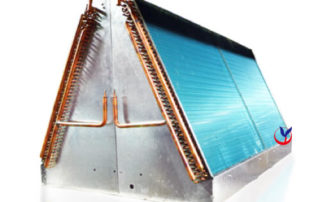

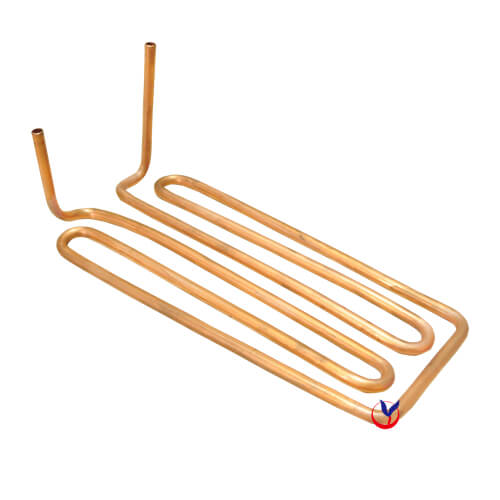

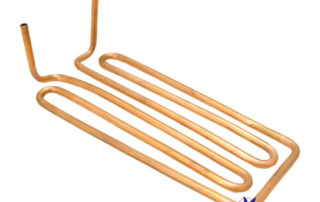

There are 3 types of ice maker condenser. The most popular type, air-cooled ice machines are equipped with fans that move fresh air across their condensers to cool the equipment. A popular alternative to air-cooled ice machines is equipment with remote condensers. Instead of being contained within the ice maker itself, a remote condenser is housed in a piece of equipment that is installed in a separate location,the biggest advantage being that they move the noise- and heat- generating components of an ice machine outside the building. A third category of ice machine is the water-cooled type. The establishments that benefit the most from water-cooled ice machines are ones with water-circulating chiller systems that are often significantly more efficient than other types.

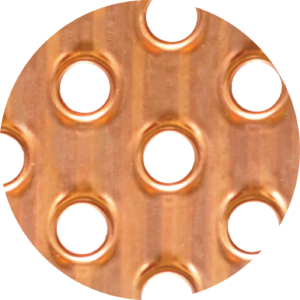

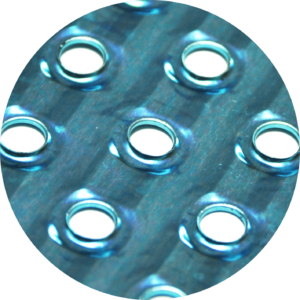

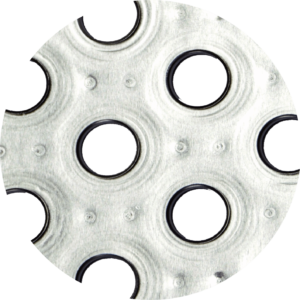

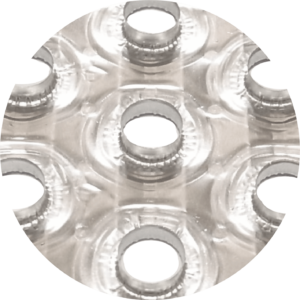

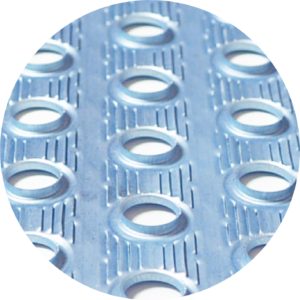

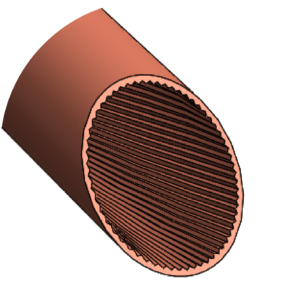

Whether air-cooled, water-cooled or remote type, the condenser is a device or unit used to condense a substance from its gaseous to its liquid state, by cooling it. In so doing, the latent heat is given up by the substance and transferred to the surrounding environment. Aluminum fin designed to maximize heat exchanger’s surface area in contact with the cooling medium surrounding it. So, the performance of Aluminum fins punching process has great effect on heat exchange efficiency. Our engineering team optimize the parameters of fin press machine including height, speed, stroke, pressure and stamping time according to different material(Aluminum or Copper) and fin thickness.